Why set up metrological follow-up for constant-temperature ovens and stability chambers?

Many materials tests involve special conditioning of specimens in order to simulate their behaviour under the combined effects of temperature and humidity of air. In order for these tests to be reproducible and equivalent over time or from one laboratory to another, the equipment used for generating the required environmental conditions (constant-temperature ovens or stability chambers) must comply with specifications defined beforehand.

Guideline document FD X 15-140 (by French standards organization AFNOR) defines a procedure for metrological characterization and verification of such equipment, including an evaluation of the associated measurement uncertainties. In France this document is largely seen as a formal document for metrological verification.

What are the principal new features of the August 2024 version of guidance document FD X 15 140?

The new version of the document has kept the same general outline regarding the characterization procedure. One of the main changes lies in the minimum number of sensors to be installed for mapping, in accordance with the volume of the work space.

For common cases it is now necessary to switch from 9 to 15 sensors if the work space defined by the customer is larger than 1 m3 (previously the cut-off was 2 m3).

Legend: 1 Work space / 2 Internal volume

Other changes have been made to the list of components of uncertainty to be taken into account, where applicable. In particular, there is mention of the additional component of uncertainty linked to the effects of radiation from the walls.

Services offered by CERIB

CERIB has flexible-scope accreditation (flex3) in the field of constant-temperature ovens and stability chambers (formerly programme 122-2 – Cofrac Testing No. 1.0001; scope available at www.cofrac.fr).

Implementation of the new version of FD X-15-140 for oven characterization provided an opportunity to introduce some changes to the formalization of reports, particularly as regards more detailed presentation of the exact positions of sensors at the time of characterization.

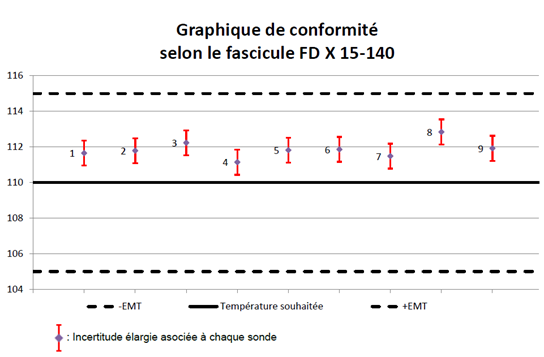

The verification still includes a summary graph showing the average of the temperatures recorded at each sensor and the associated measurement uncertainties against the acceptance criteria (maximum permissible errors: dashed lines).

Our metrology training courses afford an opportunity to give detailed technical information on choosing standards of measurement, characterizing ovens and on the approaches for interpreting the associated metrological documents.